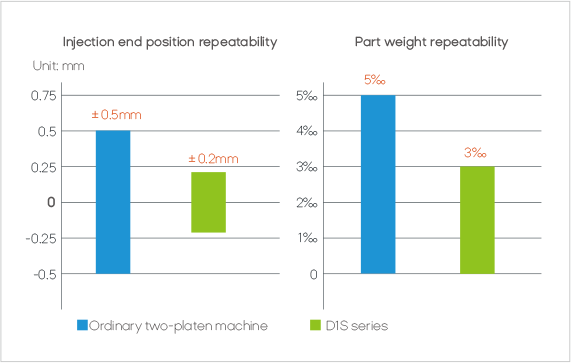

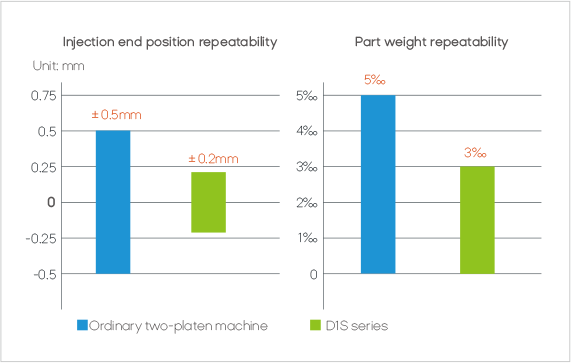

Stable injection end position High repeatability of part weight

Linear guide rails, with the benefits of low resistance and quick acceleration, are a standard feature of D1S series two-platen injection molding machine. Incorporating other features, such as ultrasonic displacement sensor for monitoring and full closed-loop injection, D1S series has achieved accurate position control and high repeatability of part weight.

- Excellent injection repeatability

Repeatability of injection end position up to ±0.2mm or less and repeatability of part weight 0.3%.

- Non-contacted ultrasonic displacement sensor

Ultrasonic displacement sensor for position measurement is characterized by absolute value, little signal interference, long service life and high accuracy of measurement.

- Integral linear guide rails for injection

Linear guide rails are a standard feature of D1S series, bringing benefits of low resistance, quick acceleration and stable injection.

- Adaptive PID temperature control

With the use of durable ceramic heater bands and adaptive PID control performed by the Austrian controller, temperature control accuracy is up to ±0.5℃.

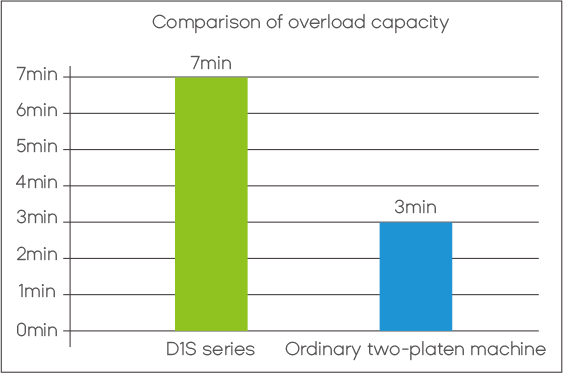

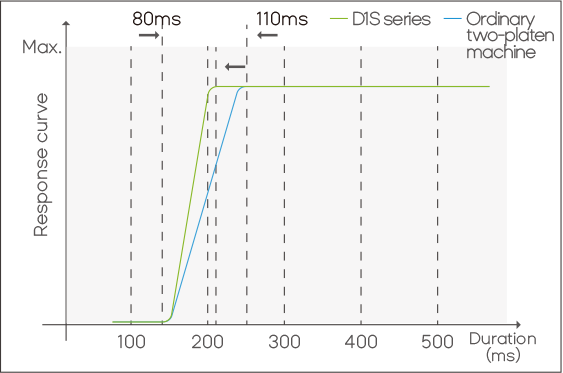

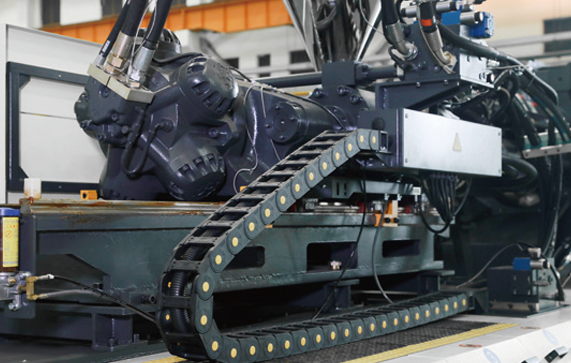

Fast response, strong overloading, stability, energy conservation

D1S series is based on a hydraulic system with stability and fast response at the core, which enables hydraulic circuit to be in optimal operating conditions. The hydraulic system is characterized by fast response, strong overload capacity and low energy consumption that meets China energy efficiency grade 1.

New-generation servo system driven by fully oil-cooled motor

The fully oil-cooled two-headed motor-driven servo system is the quintessence of highly-integrated servo pump system. It eliminates the influence of instability in machine operation due to the work environment and further reduces energy consumption of hydraulic circuit. Synchronized drive technology makes hydraulic circuit response faster and movements more efficient.

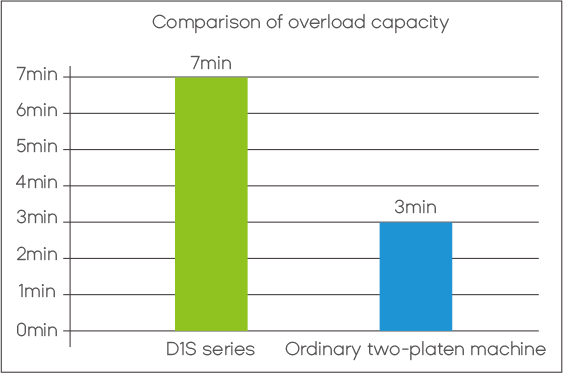

Strong overload capacity

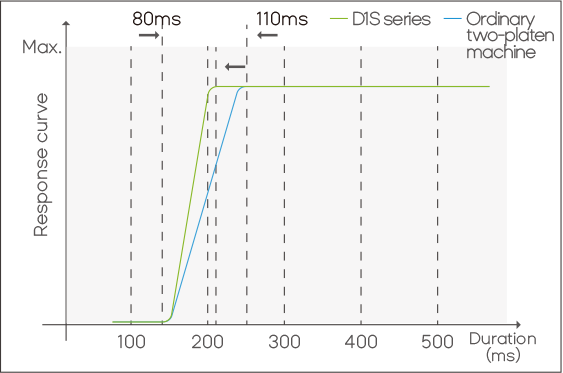

Rapid acceleration

Durable and reliable

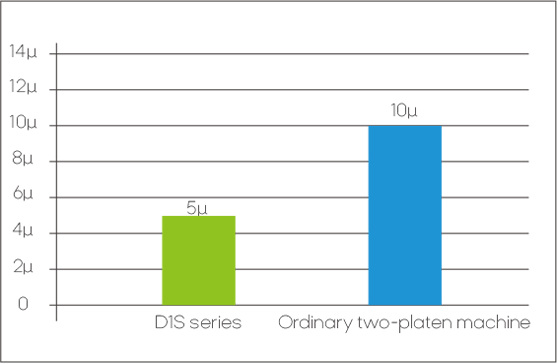

Precise filtration and independent cooling system

With independent hydraulic circuit filtration system, filter fineness is up to 5μ m and cooling effect is optimized, which ensure long service life of seals.

Machine becomes more stable.

-

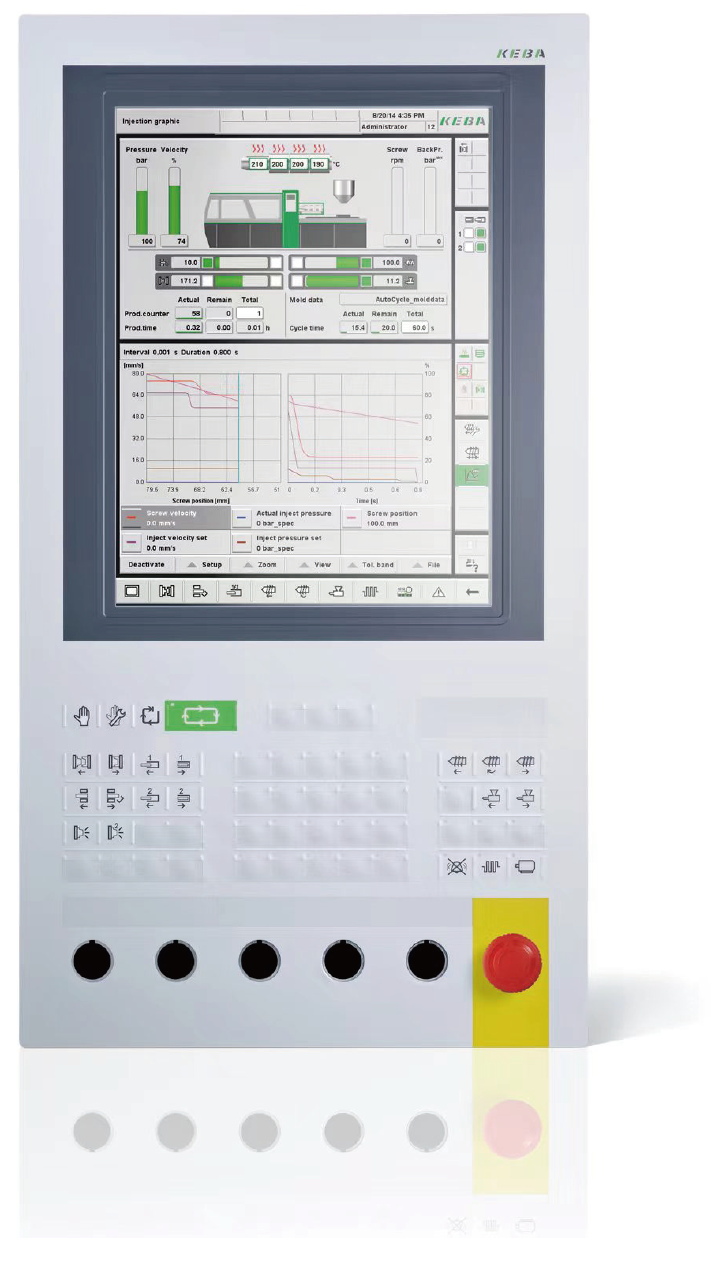

Accurate control, various functions, reliable and stable

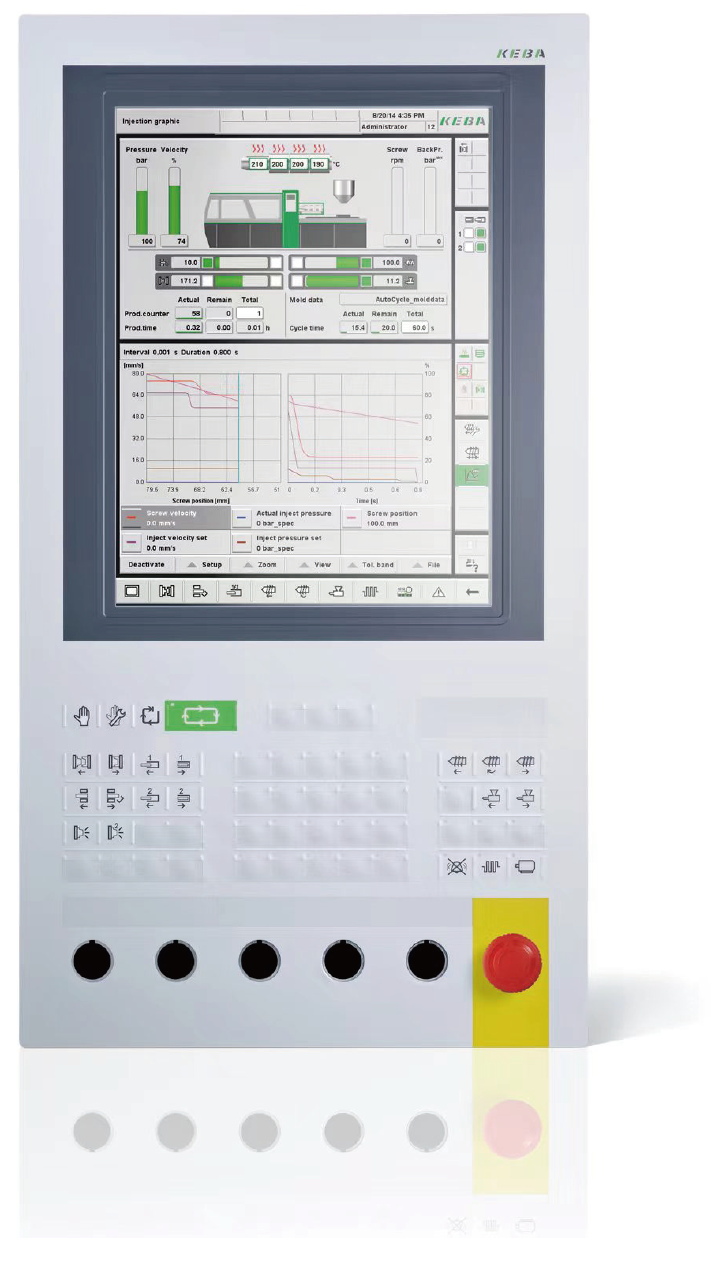

D1S series adopts Austria's KEBA control system dedicated to two-platen injection molding machine. This powerful system can accurately control the position, pressure, speed, temperature and other parameters.

The whole control system is engineered based on reliability, stability, safety and user-friendly operation for better user experience.

Stable, fast and accurate control

D1S series injection molding machine adopts Austria's KEBA control system, with double CPUs, 1ms of response time and high reliability.

DFast mold opening and closing and high repeatability thanks to the high-response dual proportional valve control technology

Servo injection (closed-loop control of injection, plasticizing, holding pressure and back pressure)

Self-tuning of temperature parameters of barrel and hot runner makes temperature control more accurate.

Various functions

Memory of alarm and process parameter change, USB expansion without limit

Programming with no restrictions, record of process parameter change curve is available

Production process data control (PDP) and statistical process control (SPC)

Multi-level user access to protect system and data

Multiple protections of equipment and people through software and hardware

New processes like MuCell, ICM, IMC can be integrated

Humanized design, easy to operate

Real-time remote control and maintenance

Online conversion of languages and units

Quick input by means of graph and virtual keyboard

Quick settings page for easy and convenient process parameter setting

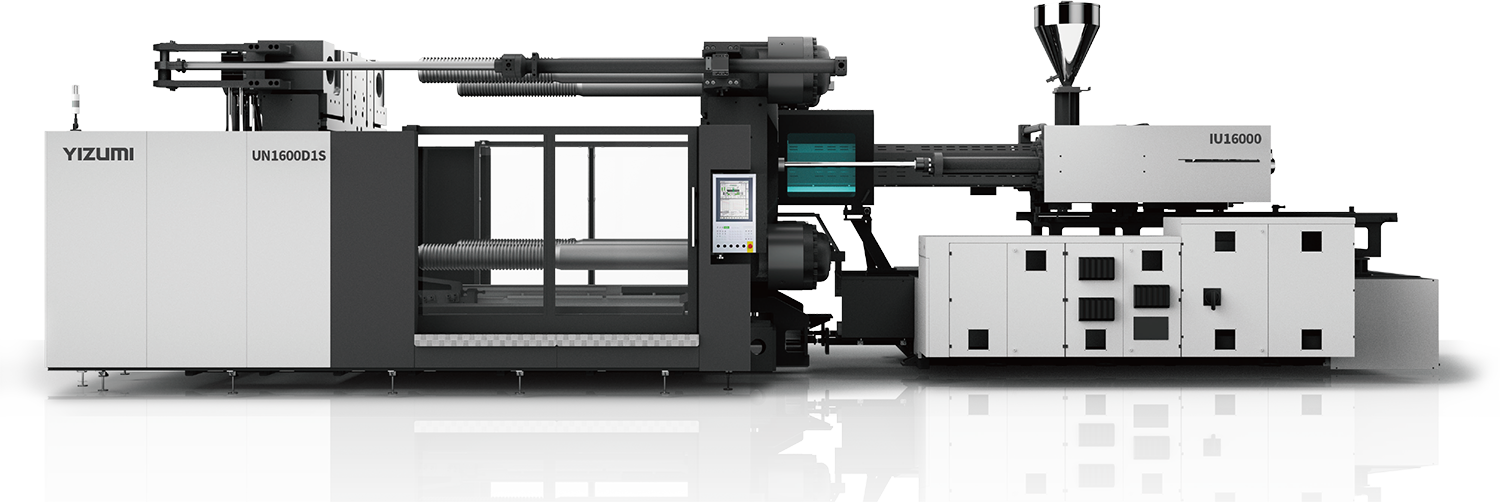

사출기

사출기