-

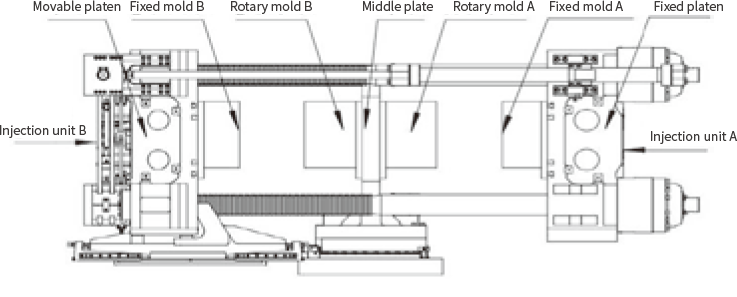

Operating principle

After simultaneous injection by A unit and B unit, the product is ejected.

Then the turntable rotates vertically by 180 degrees and the mold is closed for next-round injection. When the mold is finally opened, the molding process of two stations is completed. The rotary degree of turntable is set at 180 degrees in forward and reverse direction.

Feature

Station exchange can be achieved by rotating the turntable vertically.

Good compatibity and mature mold technology, with wider application.

Application

Widely applied in the production of multi-component products, such as auto taillight, center console panel, interior and exterior parts, appliance shell, notebook parts,etc.

-

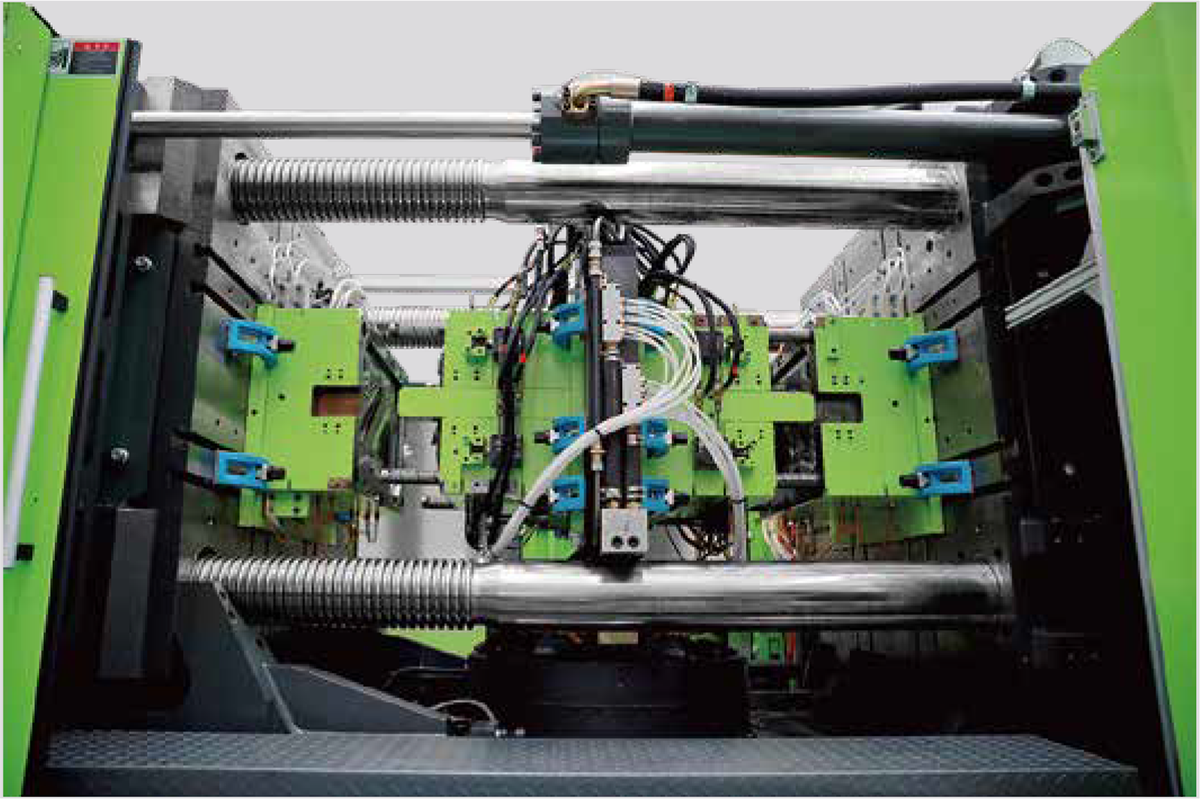

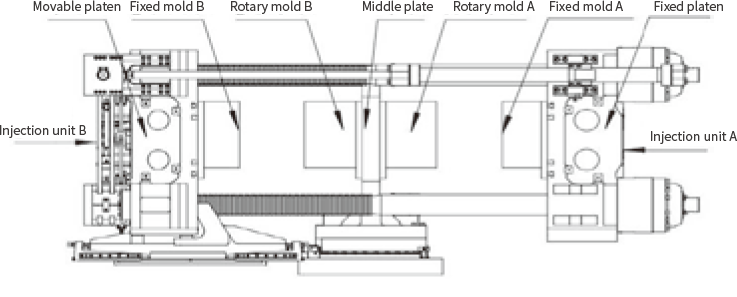

Operating principle

Injection unit B is moved along with the movable platen. The process of mold opening and closing is completed with the movement cooperation of movable platen and horizontal turntable. After mold closing, the injection by unit A and B is carried out as per process requirement. And the product is finally ejected by the core-pulling unit of middle plate or ejection unit after mold opening.

Feature

Station exchange can be achieved by rotating the turntable horizontally.

Compared with vertical turntable, horizontal turntable can help machine double the production capacity with the same clamping force setting; or largely reduce clamping force under the same production capacity as required.

Application

Widely applied in the production of multi-component products, such as auto sunroof, side window, A-pillar, B-pillar, headlight, grill, door panel, center console screen, appliance panel, outer frame

사출기

사출기