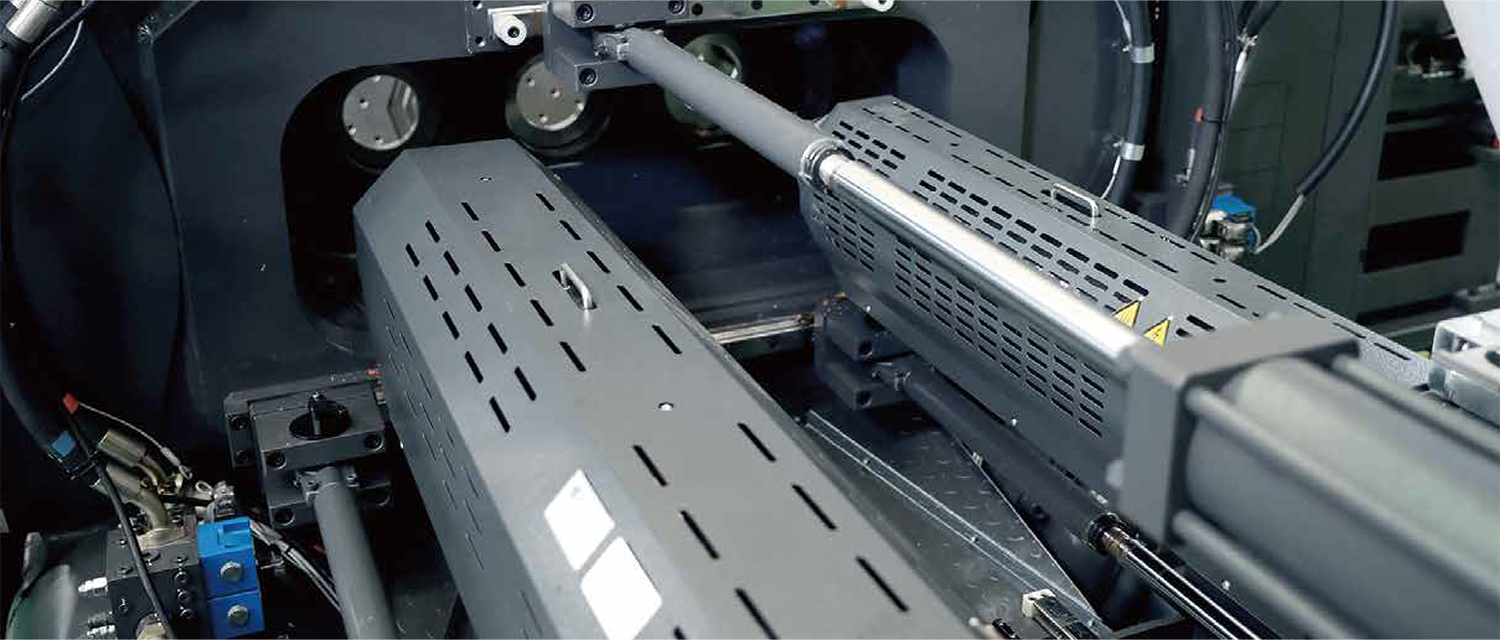

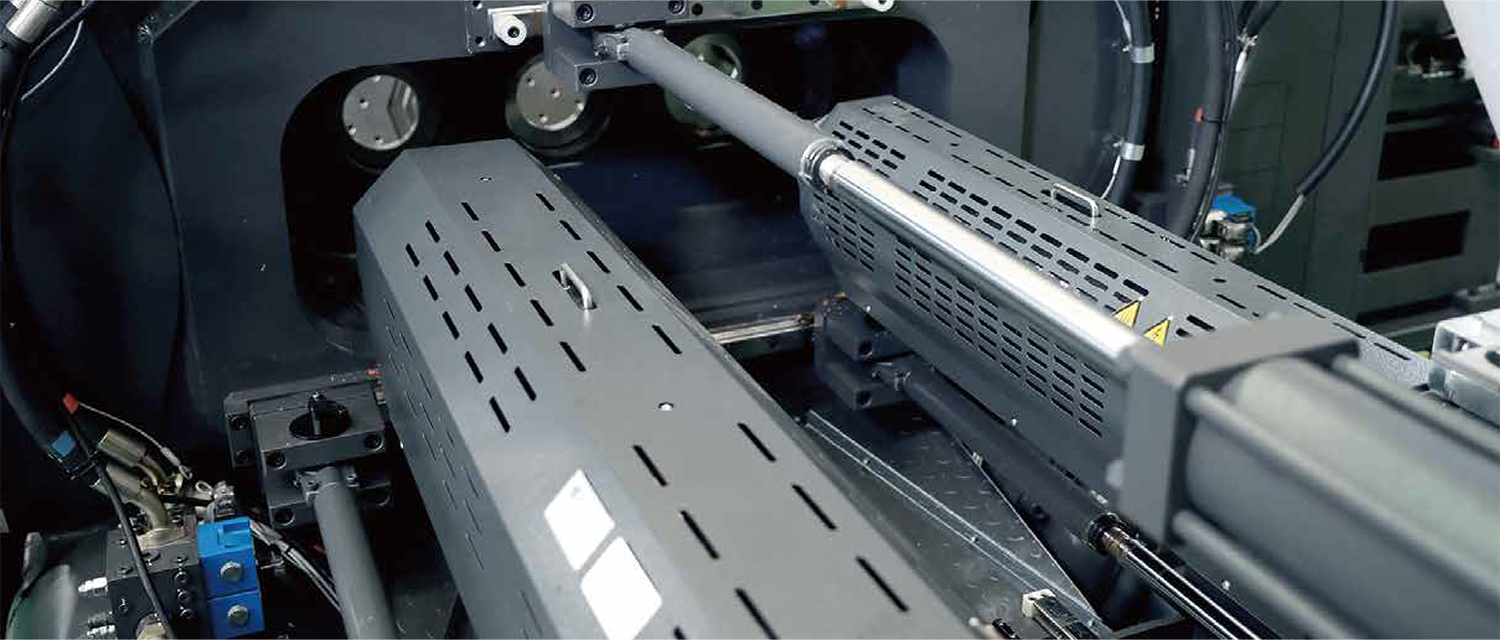

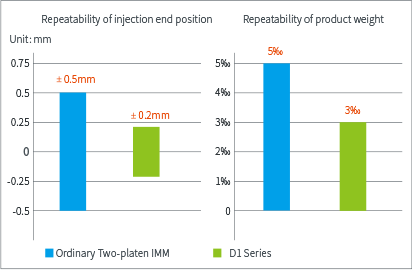

High injection repeatability

Based on European single-cylinder injection molding t echnology, it brings low injection inertia and high le ak-proof performance of cylinder; also combined with high mixing anti-stick screw and precise temperature control, injection stability is further enhanced, making the repeatability of product weight up to 3‰.

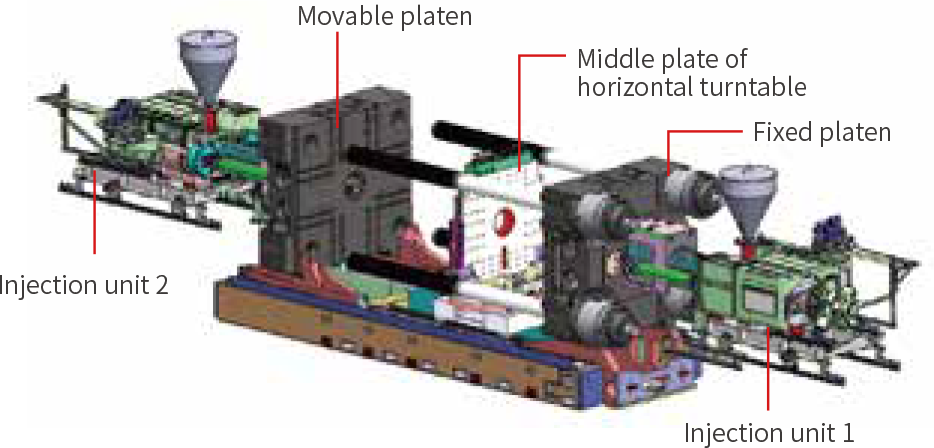

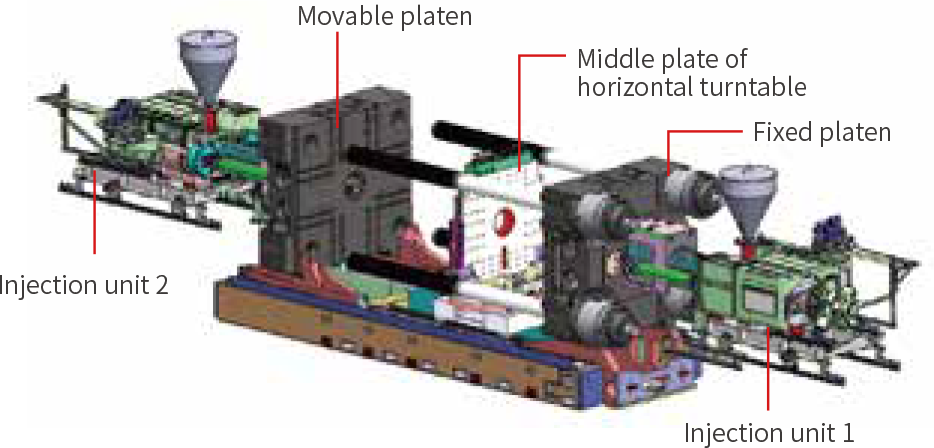

- Horizontal turntable two-way injection molding

Modular design, for easy combination.

Horizontal turntable is suitable for the molding of long or large two-color products.

It can help machine largely reduce clamping force comparing with vertical turntable. Also horizontal turntable can cooperate with the third and the fourth injection units(W type, L type, V type, etc.) in multi-component molding, providing more cost-effective solution.

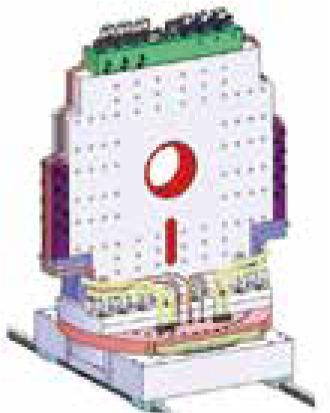

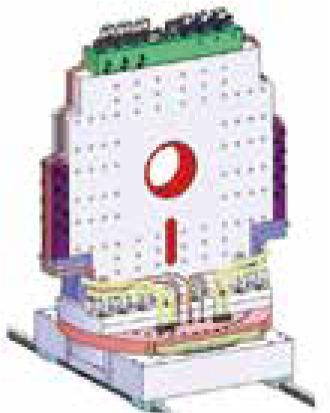

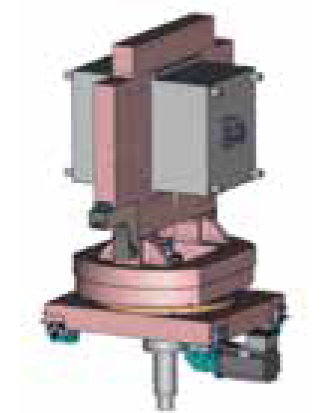

Middle plate of horizontal turntable

-

-

Core

Hydraulic ejector

Electronic signal

Cooling water

Steam

-

-

Applied with German automatic flow distribution shaft system and double layer structure for oil-water separation, integrated management for oil, water and gas is achievable. Clockwise rotation is also available by 90°, 180° or 360°,

no tangling for pipeline.

Structure: Two-platen IMM + two injection units + horizontal turntable and middle plate

Technical advantages

Compared with traditional stack molds

Using two independently controlled injection units to better control injection volume

High flexibility, two different molds can be used synchronously

Reduce length of hot runner for lower cost

Improved hot runner balance for faster debugging and startup

Reduce dwell time of raw materials in the barrel

Less raw material degradation and better quality control

Compared with machine with vertical turntable

More flexible, applicable to the production of large two-color parts

With double cavities and output under the same tonnage, more economical

Nearly half of the required machine tonnage under the same production capacity requirement, less power consumption and lower cost.

Provide innovative solutions such as cubic molds using the horizontal turntable

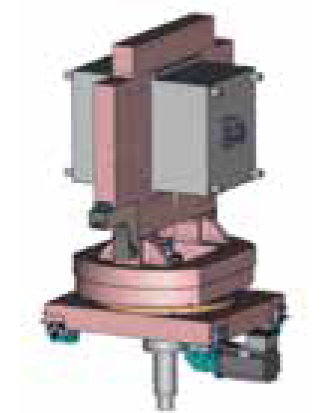

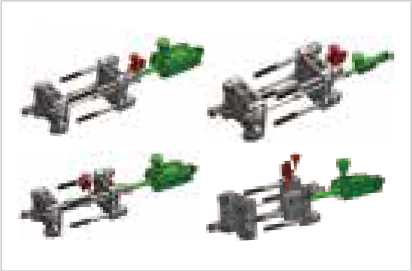

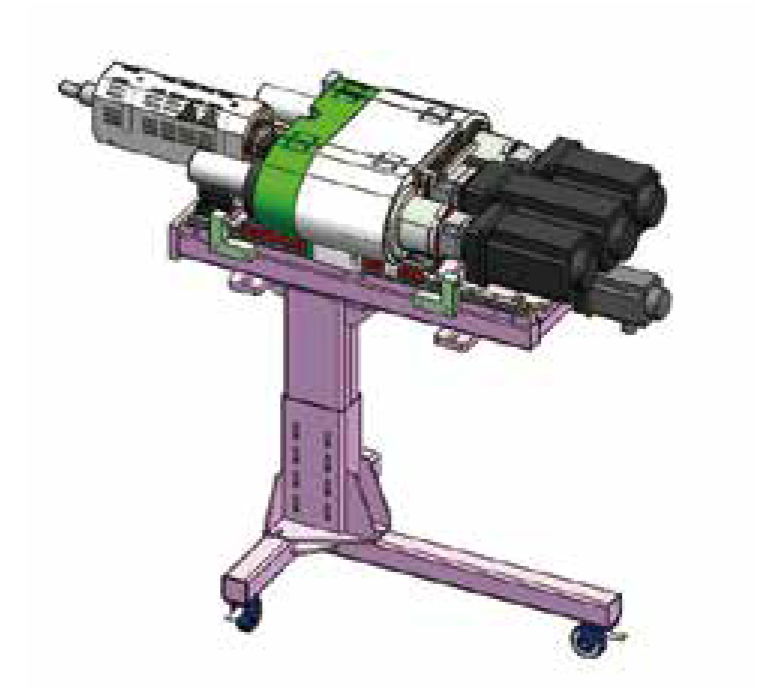

Independent electric injection unit

Independent modular design

With modular design, it can be combined with hydraulic machine to be an oil-electric hybrid multi-component injection molding machine; or combined with all-electric machine to be an all-electric multi-component injection molding machine. Flexible combination like type, W type and V type combination is available for wider application.

Note: Its specific structure is subject to the actual design. The base rotation function is optional.

Compact design, easy to install and store

Using all-electric control for injection, plasticizing and injection carriage, compact structure and easy to install and store.

Servo control

High injection repeatability, fast response and more stable molding.

Flexible combination

Can be combined as L type or V type injection unit, adaptable to different molds.

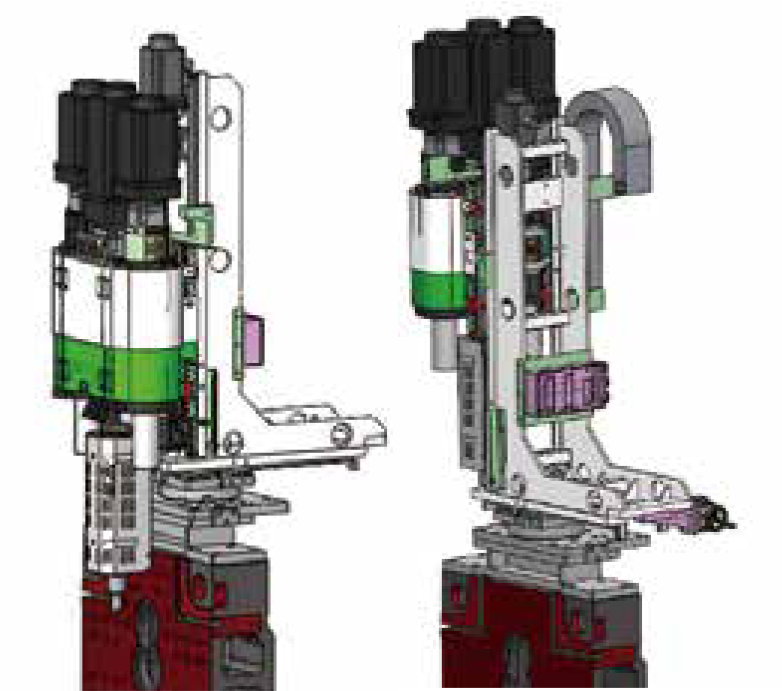

Base rotation (Optional)

Base rotation can help offer more space for m old loading, unloading and maintenance; Secondary injection unit can also be combined with the main injection unit through base rotation by 180 degrees to achieve sand - wich molding.

Clean and environmental friendly

All-electric control is cleaner than the hydraulic control, especially suitable for the clean production with lower energy consumption.

High compatibility

It can be compatible with different brands or different tonnages machine to achieve two-color or multi-color molding, low operating cost.

사출기

사출기