Precise control, reliable and stable, user-friendly design

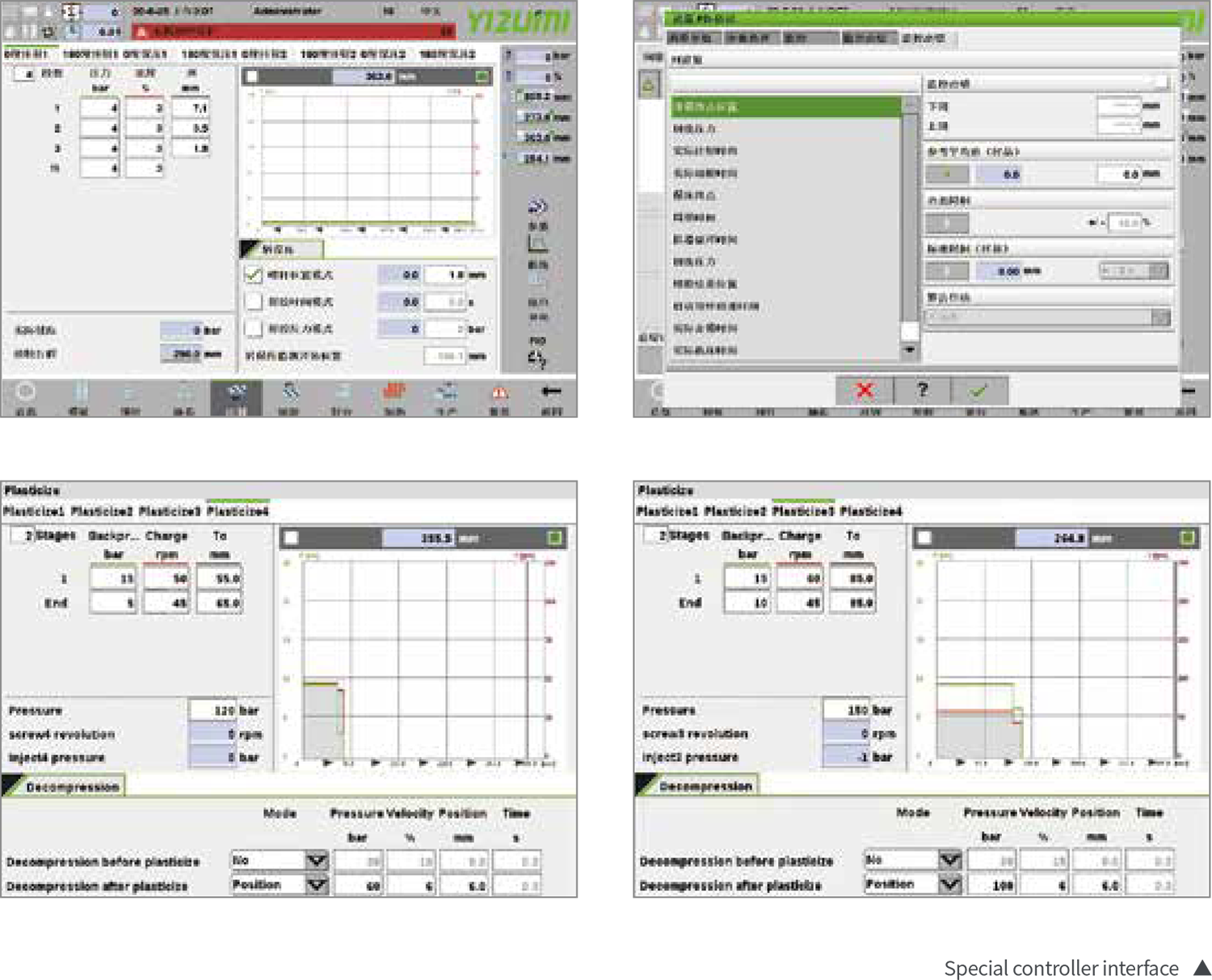

Austrian KEBA controller is standard for two-platen multi-component injection molding machine. Controller design is reliable, stable, safe and user-friendly, applicable to various multi-component molding solutions, improving customer experience.

Dual CPU control, 1ms scanning cycle and high r eliability to ensure that the operation time of each injection unit is limited to 1ms.

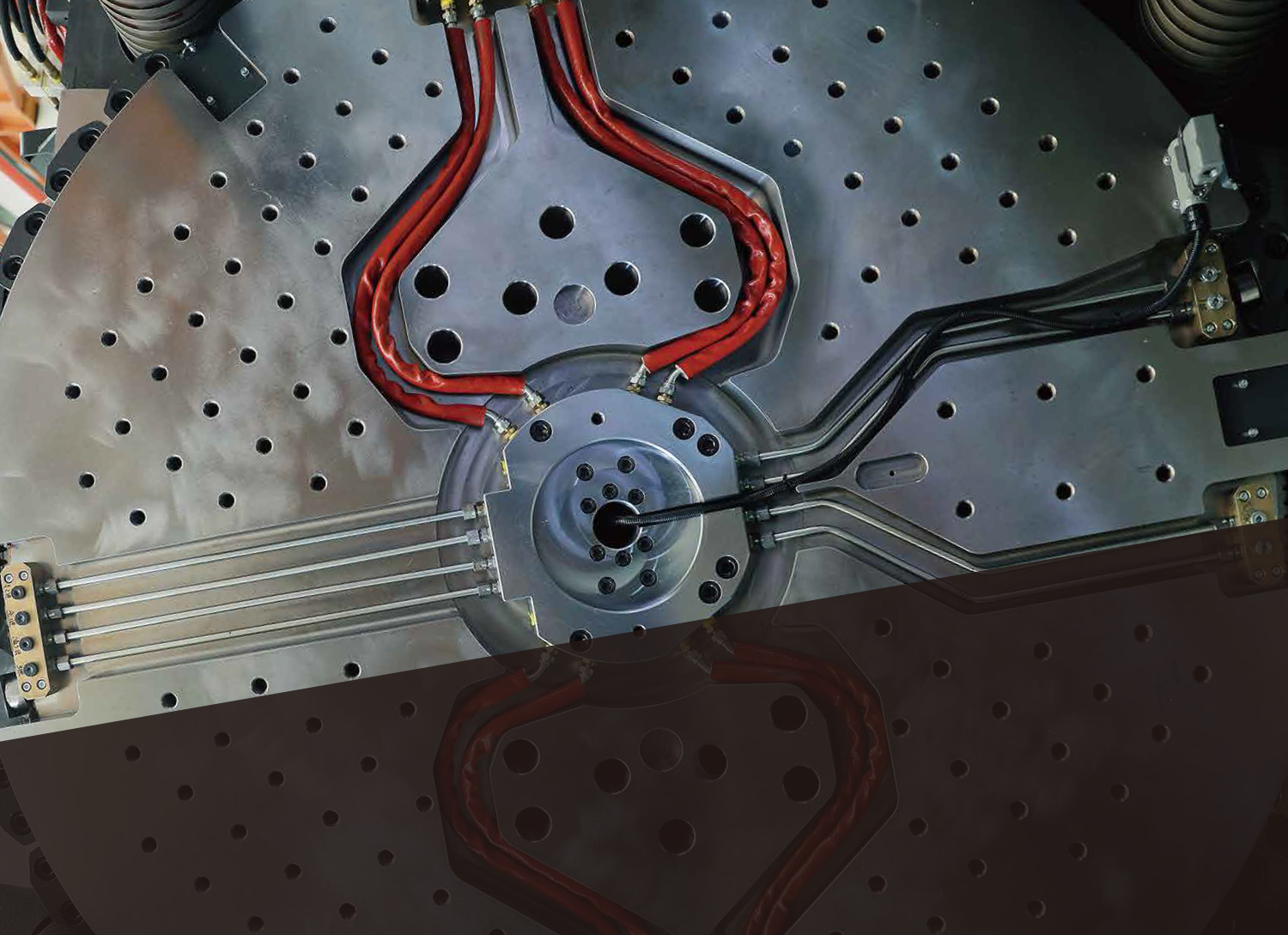

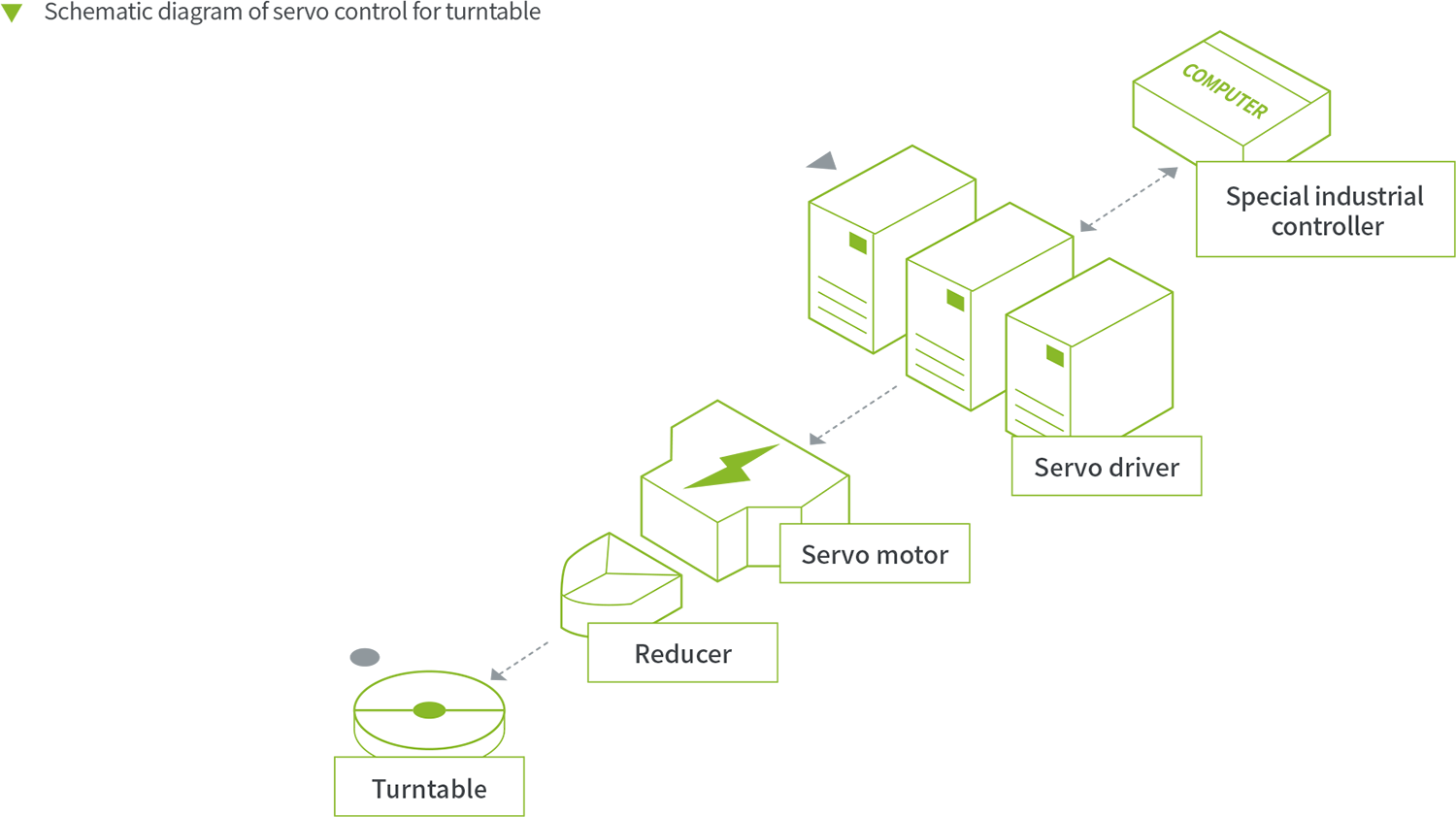

Synchronous communication technology and servo closed-loop positioning technology to achieve more accurate turntable positioning.

The latest generation of PID closed-loop temperature control technology can obtain more accurate temperature control.

USB port with storage extension can be served as mold data memory, easy and convenient.

Memory functions of alarming and process parameter changing.

Curve recording function for process data changes.

Process Deviation Procedure(PDP)and Statistical Process Control(SPC).

Multi-level user access management and data protection ensure data security.

Real-time remote control and operation.

Online multi-language, easy for language switching.

Fast input of icons and virtual keys.

Quick set of screen and easy set of process parameter.

Expandable I/O modules to integrate more functions such as built-in hot runner control and sequence valve function.

Communication ports for printers, auxiliaries and automation can be expanded to OPC/UA communication interfaces.

사출기

사출기